The aircraft is typically controlled by a set of 20–70-foot lines usually of multi strand stainless steel, single strands of piano wire, or G.S.U.M.P. (Gel Spun Ultra-high-molecular-weight polyethylene, made by DuPont). For sport flying, non-metallic lines of kevlar, dacron, or other low-stretch fiber materials are commonly used. This type of control was originally trademarked as "U-Control" and is by far the most common control method.

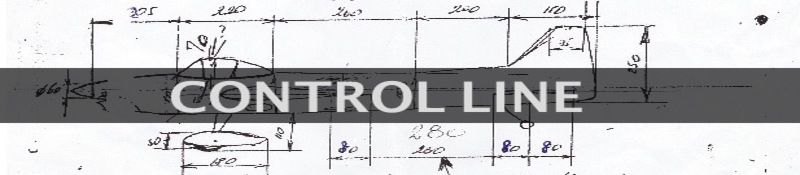

The controls of a conventional 2-line/"U-Control" system consist of lead-out cables, a bellcrank, push rods and control horns. These are connected so that differential motion of the lines rotates the bellcrank, causing a pushrod to move either forward or aft. The pushrod is connected to the control surface with a control horn that moves the elevator (and flaps, if used) up and down. The pilot holds a handle to which the lines are attached. Tilting the handle with the fingers, wrist, and/or elbow motion causes the differential movement in the lines. By convention, tilting the hand so the top is closer to the pilot than the bottom results in "up" elevator, much like pulling back on a full-scale airplane control stick. Also by convention, most airplanes are flown nominally counter-clockwise as viewed from above, with the leadout cables exiting the left wing. This is not universal and some pilots fly in the opposite direction. Flying clockwise has a slight advantage in some situations because most engines run so that the torque will roll the airplane away from the pilot, increasing line tension in upright level flight.

The controls can be expanded by adding a third line that controls the throttle. The most common system for throttle control is that devised by J. Robert Smurthwait, of Baker Oregon, and is widely available. The throttle is usually a conventional carburetor as used on radio control models schemes that couple limited rudder and/or aileron, and variable leadout position are often found on carrier planes as well as elevator and flaps/ Monoline control works by twisting the single line. The pilot holds a handle with a twisted flat piece of metal on bearings in one hand, and a "bobbin" in the other. Moving bobbin towards or away from the handle twists the line. Inside the airplane, the rotating line rotates a spiral scroll with a follower. The follower moves toward and away from the pivot of the scroll, and has a pushrod attached. Then, as the scroll rotates, the pushrod moves fore and aft. The rest of the system is like the two-line system. The control of a monoline system is much less precise than a two-line system because the line itself tends to twist up before it moves the scroll, leading to a somewhat vague control response with considerable lag. It does however have the advantage of not requiring as much line tension to move the controls, and the single line has less drag than the two slightly smaller lines used in conventional two-line control.

No comments:

Post a Comment